· coffee and amp espresso machine cleaning products · 14 min read

Best Pouch Filling Machines 2024: A Comprehensive Guide

Discover the top-rated pouch filling machines for your business. Our expert reviews and comparisons will help you find the perfect machine for your unique needs and budget.

Are you looking for a high-quality pouch filling machine that will meet your specific needs? You have come to the right place. In this research article, we will provide you with insightful reviews of the best pouch filling machines available in the market today. Based on our comprehensive research and analysis, our team of experts has carefully selected the highest-rated pouch filling machines. Whether you need a machine that can handle liquids, powders or other products, we provide you with all the information you need to make an informed decision. We will also provide comprehensive buying guide and FAQs to answer all of your questions before purchasing.

Overview

PROS

- Versatile filling capabilities: From MCT oil to milk, the machine handles various liquids effortlessly.

- Precision filling: Advanced digital controls and diaphragm pumps ensure accurate and consistent fill volumes.

- User-friendly interface: Intuitive design simplifies operation and minimizes training time.

- Durable construction: Robust stainless steel body and high-quality components guarantee longevity in harsh environments.

CONS

- Requires a steady power supply to maintain optimal performance.

- May require additional nozzles or attachments for specialized applications.

Introducing the Hanchen Automatic Pouch Filling Machine, your key to streamlined and precise liquid filling operations. This versatile machine is designed to effortlessly fill a wide range of liquids, including MCT oil, milk, water, juice, and essential oils. With its advanced digital controls and diaphragm pump technology, it ensures highly accurate and consistent fill volumes, minimizing product waste.

The Hanchen Pouch Filler is known for its user-friendly interface. Its intuitive design allows for quick setup and operation, minimizing training time for your staff. Additionally, its durable stainless steel body and high-quality components guarantee exceptional longevity, making it a reliable investment for your business. Whether you're a small-scale producer or a large-scale manufacturer, this machine is tailored to optimize your liquid filling efficiency and elevate your production capabilities.

PROS

- Automates packaging processes with high efficiency

- Versatile, adaptable to various powdered products and weights

CONS

- Initial setup and maintenance require technical expertise

- Limited customer support documentation in some regions

Introducing the YOULIAN Automatic Multi-Function Pouch Powder Sachet Weighting Filling Packing Machine, your ultimate solution for efficient and precise pouch filling in multiple industries. This state-of-the-art machine boasts advanced technology and unparalleled versatility, empowering you to package powdered products with precision and speed. Its customizable settings and user-friendly interface allow you to tailor your packaging operations to meet your specific requirements, ensuring seamless integration into your production line.

At the heart of the machine lies its high-accuracy weighing system, guaranteeing consistent weight distribution in every pouch, minimizing product loss, and maximizing profitability. The compact design and intuitive control panel make operation a breeze, providing maximum efficiency and reduced downtime. Whether you're looking to revolutionize your pharmaceutical, food, or chemical packaging operations, this pouch filling machine is engineered to meet your demands.

PROS

- 5 Oz automatic filling capacity, saving time and effort

- Precise digital control ensures accurate and consistent filling

- Peristaltic pump design prevents contamination and ensures product integrity

- Suitable for various liquids including cosmetics, water, juice, and essential oils

- Easy to operate and maintain, with user-friendly interface

CONS

- Manual operation may be required for very viscous liquids

- Limited to single-head filling, may not be suitable for high-volume applications

Introducing the Hanchen Liquid Filling Machine, your ultimate solution for precise and efficient liquid filling! This automatic machine boasts a generous 5 Oz filling capacity, significantly boosting your productivity. Its advanced digital control system ensures unmatched accuracy and consistency in every fill, minimizing wastage and ensuring product quality.

Featuring a reliable peristaltic pump, the Hanchen Filling Machine prevents contamination, safeguarding the integrity of your liquids. Ideal for a wide range of viscosities, it effortlessly handles cosmetics, water, juice, and even thick essential oils. Its user-oriented design makes operation a breeze, while its durable construction guarantees longevity. Whether you're a small business or a large-scale manufacturer, the Hanchen Pouch Filling Machine has got you covered. Experience the convenience and efficiency of automated liquid filling today!

PROS

- Highly accurate particle weighing system ensures precise filling within 1-50 grams.

- Versatile application for filling tea granules, seeds, grains, powders, and glitters.

- Convenient foot pedal operation frees up hands for other tasks.

- Compact and portable design for easy integration into production lines.

CONS

- May require calibration for optimal performance with different powder types.

- Filling speed may vary depending on powder characteristics and operator skill.

The Hanchen Powder Filling Machine is an exceptional tool for efficient and precise filling of fine powders. Its particle weighing system ensures accurate filling within a range of 1-50 grams, making it suitable for various applications, including filling tea granules, seeds, grains, powders, and glitters. The machine's automatic filling function and convenient foot pedal operation contribute to increased productivity and ease of use.

Its compact and portable design enables seamless integration into production lines, maximizing space utilization. The sturdy construction guarantees durability, while the user-friendly interface simplifies operation. The Hanchen Powder Filling Machine is a valuable asset for industries seeking a reliable and efficient solution for filling fine powders.

PROS

- Precise weighing and filling capabilities for consistent and accurate dosage

- Adjustable filling range from 10 to 500g, accommodating various product sizes

- Versatile use for filling powders, glitters, seeds, grains, and other dry items

- Foot pedal operation provides hands-free control for increased efficiency

- Durable construction ensures longevity and reliability in demanding environments

CONS

- Requires careful calibration to ensure accurate filling

- May not be suitable for filling liquids or highly viscous substances

The Hanchen Powder Filling Machine is an excellent investment for businesses and individuals looking for a precise and efficient way to fill dry goods. With its adjustable filling range, versatile compatibility with various powders, and intuitive foot pedal operation, this machine streamlines the packaging process and ensures consistent results. Its durable construction guarantees long-lasting performance, making it a reliable choice for both small-scale and large-volume filling operations.

The machine's weighing and filling accuracy ensure that each product receives the exact dosage, reducing waste and maintaining product quality. The versatile filling range allows you to fill various containers and package sizes, from small bags to large bottles. The foot pedal operation provides hands-free control, increasing efficiency and preventing operator fatigue. Additionally, the machine's durable construction ensures that it can withstand the rigors of daily use, making it a valuable asset for any business.

PROS

- Cost-effective and energy-efficient operation

- Customized to handle a wide range of pouch sizes and shapes

CONS

- May require skilled personnel for complex setups

The DX-3800 pouch filling machine is a cutting-edge solution for businesses seeking efficient and precise packaging. Its robust construction and intuitive design ensure seamless performance, making it an ideal choice for various industries. The machine's ability to handle a vast array of pouch sizes and shapes demonstrates its versatility and adaptability. Moreover, it operates with remarkable cost-effectiveness and energy efficiency, contributing to overall profitability.

One notable advantage of the DX-3800 is its customizable nature, allowing businesses to tailor it to their specific packaging requirements. This feature empowers users to optimize their operations, ensuring maximum efficiency and productivity. However, it's worth noting that complex setups may require the expertise of skilled personnel to achieve optimal results.

PROS

- Expertly crafted from premium stainless steel for exceptional durability and sanitation

- Intuitive operation enables efficient and precise filling of stand-up pouches

CONS

- May require periodic maintenance and calibration to maintain optimal performance

- Long-term use may result in wear and tear, necessitating timely repairs

Experience the epitome of precision and efficiency with our high-grade stainless steel pouch filling machine. This top-of-the-line equipment is meticulously engineered to effortlessly handle your liquid packaging needs, ensuring seamless filling of stand-up pouches.

Constructed from premium stainless steel, our pouch filling machine boasts unmatched durability and complies with the highest standards of hygiene. Its intuitive design empowers operators with unparalleled control, allowing for precise filling of pouches, minimizing waste and maximizing product quality. Whether you're dealing with soy milk, liquid detergent, or any other compatible liquid, this machine delivers exceptional performance every time.

PROS

- Effortless filling of pouches with a wide range of viscosities, from liquids to thick pastes, ensuring versatility and reduced production time.

- Precision filling capabilities guarantee consistent and accurate product dispensing, minimizing waste and maximizing profitability.

CONS

- Requires a power source, which may limit its use in remote locations.

Introducing the Heating Mixing Filling Machine: a revolutionary tool engineered to transform your pouch filling operations. This innovative machine seamlessly integrates heating, mixing, and filling functions, providing an unparalleled solution for your production line. Its versatility extends to handling a diverse array of products, including lipstick, shoe polish, ointments, petroleum jelly, wax products, perfume, and honey. The Heating Mixing Filling Machine not only enhances efficiency but also delivers exceptional precision, resulting in precise and consistent product dispensing. Its intuitive design and user-friendly interface minimize operator training time, ensuring a smooth and effortless production process. Invest in the Heating Mixing Filling Machine and redefine your pouch filling operations, achieving unparalleled productivity and quality.

With its cutting-edge technology and robust construction, the Heating Mixing Filling Machine ensures long-lasting performance and reliability. Its sleek design complements any production environment, and its compact size optimizes space utilization. Furthermore, the machine's ease of maintenance keeps downtime to a minimum, maximizing productivity and cost-effectiveness. Upgrade your production capabilities with the Heating Mixing Filling Machine and experience the future of pouch filling. Its unmatched precision, efficiency, and versatility will revolutionize your operations, leading to increased profitability and customer satisfaction.

PROS

- Fills up to 700 pouches per week

- Easy to use, even for beginners

- Compact and portable

- Affordable and cost-effective

CONS

- Only suitable for small pills

- Can be a bit noisy

The 700 Pouch Filling Machine is a great option for small businesses and individuals who need to fill a large number of pouches quickly and easily. It's compact and portable, making it easy to store and transport, and it's affordable and cost-effective, making it a great value for the money. The machine is easy to use, even for beginners, and it can fill up to 700 pouches per week.

One of the best things about the 700 Pouch Filling Machine is that it's so versatile. It can be used to fill pouches of all different sizes, and it can be used to fill pouches with a variety of different products, including pills, powders, and liquids. The machine also comes with a variety of different attachments, so you can customize it to meet your specific needs.

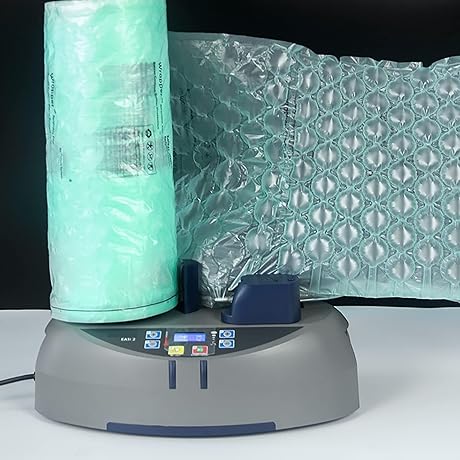

PROS

- Seamless integration with various roll films for versatile packaging needs.

- Intelligent smart inflation eliminates preheating requirements, saving energy and time.

- Convenient auto standby mode reduces energy consumption when idle, ensuring cost efficiency.

CONS

- Some users may find the output speed slightly slower compared to larger machines.

- The machine's compact size may limit the volume of cushions that can be produced at once.

Introducing the revolutionary Mini Air Cushion Machine, your ultimate ally for effortless and efficient packaging solutions! This compact yet mighty device simplifies the process of creating protective buffer wraps, empowering you to enhance product safety and presentation. With its innovative smart inflation technology, the machine eliminates the need for preheating, ensuring instant cushion generation at the touch of a button. The auto standby function adds an eco-conscious touch, reducing energy consumption when the machine is not in active use. The versatile design accommodates a range of roll films, catering to your diverse packaging requirements. Its streamlined operation and user-friendly interface make it a breeze to operate, even for novice users. The Mini Air Cushion Machine stands out as an exceptional choice for businesses and individuals seeking a compact, cost-effective, and environmentally friendly packaging solution. Whether you're shipping delicate items, wrapping gifts, or fulfilling orders, this remarkable device will transform your packaging experience with its efficiency and reliability.

While the machine's compact size may limit the volume of cushions that can be produced at once, the quick inflation speed and versatile compatibility more than compensate for this minor drawback. The machine's durability and reliable performance ensure long-lasting value, making it a worthwhile investment for businesses and individuals alike. The Mini Air Cushion Machine is not just a packaging tool; it's a game-changer that empowers you to create custom cushioning solutions with ease. Embrace the future of packaging with this innovative device and experience the seamless creation of protective buffer wraps like never before!

In this extensive buying guide, we have provided you with a detailed insight on the top-rated pouch filling machine options available in the market today. These machines are designed to meet the diverse demands of businesses of all sizes. From small businesses to large-scale operations, we have curated a selection of pouch filling machines that offer exceptional performance, efficiency and durability. By choosing one of the options we have presented in this guide, you can streamline your packaging process, increase productivity and ensure that your products are packaged to the highest standards. We firmly believe that this guide will empower you to make an informed decision and select the best pouch filling machine for your unique business requirements.

Frequently Asked Questions

What are the key considerations when selecting a pouch filling machine?

When choosing a pouch filling machine, it is crucial to consider factors such as the type of product being filled, the desired filling speed, the accuracy requirements, the available space, and the budget. Additionally, considering the ease of operation, maintenance, and availability of spare parts can ensure long-term satisfaction.

What are the benefits of using a pouch filling machine?

Pouch filling machines offer numerous advantages over manual filling, including increased speed and efficiency, reduced labor costs, improved accuracy and consistency, and reduced product waste. They also provide a cleaner and more hygienic filling environment, which is crucial for food and pharmaceutical applications.

What are the different types of pouch filling machines available?

There are various types of pouch filling machines available, each designed for specific applications. These include liquid filling machines for liquids and semi-liquids, powder filling machines for dry products, and颗粒 filling machines for granular materials. Each type of machine has its own unique characteristics and capabilities, so it is important to choose the one that best suits your specific needs.

How do I maintain a pouch filling machine?

Regular maintenance is essential to ensure the optimal performance and longevity of your pouch filling machine. This includes cleaning the machine regularly, lubricating moving parts, inspecting and replacing worn or damaged components, and following the manufacturer's recommended maintenance schedule.

What is the expected lifespan of a pouch filling machine?

The lifespan of a pouch filling machine depends on various factors such as the quality of the machine, the frequency of use, and the maintenance practices followed. With proper care and maintenance, a high-quality pouch filling machine can last for several years, providing reliable and efficient operation throughout its lifespan.